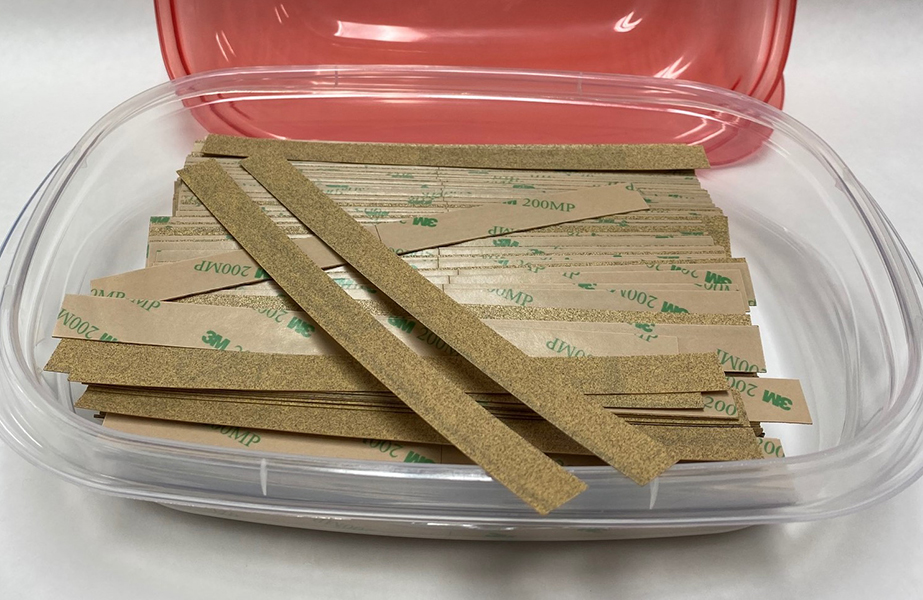

Abrasive Strips

Wear Resistance is one of the single most important attributes of surfacing products. Wear Testing (Abrasion Testing) is also one of the most costly and easily misinterpreted tests. Whether your tests include flooring, low pressure, HPL, TFM, direct pressure, or other surfacing materials, we supply abrasive strips in any quantity or configuration you require. They always include a letter of certification with the shipment to show the weight loss on the standard zinc plate. This is performed on every lot and checked on multiple abraders that have been maintained to OEM factory specifications.

Since the strips are a paper-based product, they are conditioned at 72˚F (23˚C) and 50% Relative Humidity for several days before cutting. This helps prevent changes in size due to subsequent humidity changes. They are available in original (slightly long) length or exact length to allow butting of ends without trimming.

Depending upon the test method required, these strips are available in either a 110mg weight loss or a 130mg weight loss on a zinc plate.

Our 110mg Abrasive Strips are 180 grit Aluminum Oxide, open coat on A weight base paper, glue bond. They are suitable for Wear and Abrasion testing by cycle count or weight loss methods. The 110mg Abrasive Strips are our most requested and are similar to Taber S-42 Sandpaper Strips but at a much lower cost.

Strips are sold in any quantity, but the usual method of ordering is by boxes of 500 strips in a moisture resistant box that is in a sealed plastic bag.

Let us know which test method you are using and we can help you choose the

best strip for your needs.